Glossary

Logout

©Copyright Arcturus 2022, All Rights Reserved.

7

Terms & Conditions

|

|

|

|

Security & Privacy

Contact

PRODUCT / SERVICE DEVELOPMENT

|Generic Ideas, Suggestions & Tips

Perform sensitivity analyses of the consequences of delays and cost overruns.

Delays in product development result in market introduction at a later stage than initially planned. For new products, the most profitable phase of the life cycle is the initial phase, when competition is non-existent or still weak. Delayed market introduction therefore leads to an excessive loss of profit. This phenomenon is much more serious than generally realised.

For narrow market windows delays can easily result in profit becoming lower than development costs, making the whole effort futile.

Although the effects of cost overruns and increased cost prices are relatively small compared with delays, careful monitoring of changes in projected profitability resulting from planning deviations is an absolute essential.

Intensive co-operative programmes can improve the implementation speed of new technologies.

In the transfer of ideas or knowledge everything that constitutes a barrier creates a loss of time and quality. When time is a crucial factor in bringing new ideas and technologies to the market, such barriers should be eliminated as far as possible.

A project should be chosen in which research, pre development and product development co-operate on an ad-hoc basis, if possible in a common geographical location.

Make realistic plans and stick to them. Delays in development mean delays in starting. Use formal planning procedures.

There are several causes of delays:

1. WISHFUL THINKING IN THE PLANNING PHASE

After analysing the causes of delays which have occurred in previous projects, it is quite natural to conclude that there is no need to make the same mistakes again, under the motto: Once bitten, twice shy.

However, problems have a nasty habit of cropping up unannounced and popping up from unexpected corners. It is therefore a demonstration of recklessness if an appropriate percentage of unforeseen delays is not planned in. the percentage should depend on the degree of newness of the subject. Formal planning procedures are an absolute must for improved planning discipline, in addition to a highly motivated workforce that is personally committed to the plan and its details.

2. CHANGES IN THE SPECIFICATION

Here we have one of the most widespread sources of trouble during the development process.

One principle should be adhered to:

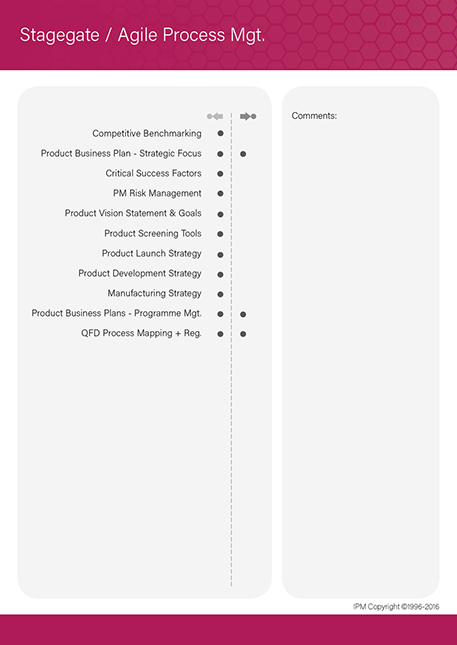

If you operate a 'StageGate' / 'PhaseGate' / 'TollGate' - a change in specification means a new plan. Never let specification changes sneak in without a realistic planning review.

3. ACCUMULATION OF RISKS

The excellent safety record of commercial airlines is largely due to the systematic elimination of risks. All important functions and indications are either duplicated or have a back up system. Safety is considered more important than the costs or weight of this extra instrumentation.

Mutatis mutandis we can conclude that the first priority for development is the timely delivery of a design with the agreed specification.

This implies that all the factors that may prevent this priority from being met must be considered and solved by providing well known back up solutions, or parallel teams working on the same subject, and it also implies that these critical factors must be recognized and analysed beforehand.

- Minimize the amount of code numbers.

- Every code number represents an unavoidable sequence of events.

It has to be specified, designed and documented. After that it has to be handled by work preparation, by planning and by the procurement department. It has to be administered, changed, fabricated, assembled, mechanized, tested, etc. and it can fail. In fact we may assume that more than 50% of our indirect workforce is directly proportional to the level of diversity, which is another way of expressing the amount of code numbers. It is regrettable that we have no direct method of calculating these effects with the normally available means of cost price calculation.

We can however safely state that those solutions that lead to the lowest quantity of code numbers must have preference under all circumstances, even if the standard cost price calculation would give a different indication. The positive effects will become visible from design through the entire process right up to service.

...Demand Simplicity!

Reduce the number of suppliers.

The principle of simplification is also valid for the procurement channel.

Fewer suppliers mean fewer interfaces, less training (see H5), less administrative work, etc. and will have a favourable influence on the amount of staff needed and the costs involved. There are other effects to be added. In the new vendor relations pattern close personal contact has to be maintained. In principle just-in-time supplies are handled on the basis of on-line information, but in case of problems (even small ones) fast action is needed by persons who have regular contacts. This is only possible when the total number of suppliers is limited.

Greater flexibility is achieved when one vendor supplies several parts, than when every part is supplied by a different vendor. For example, when vendor A supplies cabinet 1 and vendor B supplies cabinet 2 and the planning indicates a change from product 1 to product 2, and this situation is later reversed again, vendors have to change capacity twice. One vendor has to stop, the other vendor has to start, which creates problems and costs for all parties concerned.

If one single vendor had supplied both cabinets the changes would only have involved exchanging a mould on one machine.

This is only one example that demonstrates the clear and measurable advantages resulting from reducing the number of suppliers.

Active reduction of the number of suppliers should be part of the action programme of all procurement and purchasing organisations.

Lead time and planning are of significant importance in 'Research & Development' as the first link in the total innovation chain.

With the growing pressure of the competitive environment, the speed with which new ideas can be implemented is increasingly becoming a decisive factor for success. Creative ideas are difficult to plan, but since these account for only 1% of the total work, the other 99% are open to some kind of planning.

This does not conflict with research principles. Planning improves productivity; even creativity can be stimulated by pressure.

The margins to be allowed in the planning will probably have to be wider than in normal product planning schedules.

|Related Procedures

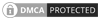

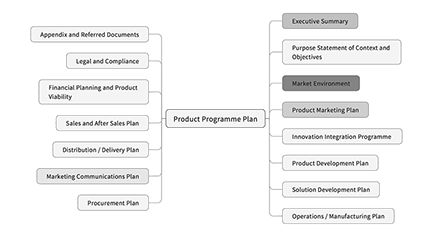

The following interrelationship maps indicate; suggested content from other models/processes which may have influence or an effect on the analysis of the title process. The left-hand column indicates information or impact from the named process and the left-hand column indicates on completion of the process/analysis it may have an influence or effect on the listed processes.

Note: A complete set (professional quality) of PMM interrelationship cards are available to purchase - please contact us for further details.

|Strategic Business Models, Workshop Tools & Professional Resources

The IPM practitioner series, is a definitive and integrated training programme for management professionals operating in the Product Management arena. So whether you’re the Managing Director, Product Director, Product Manager or a member of the Multidisciplinary Team we are confident that you will find this particular training series to be one of the best available and an invaluable asset to both you and your company.

PMM - Professional Support